Beyond the Bid: The Importance of Technical Proposals in the RFQ Process

When issuing a request for proposal (RFP) or request for quote (RFQ) for precision metal fabrication projects, government entities and contractors aren’t just looking for a list of line items with associated costs. They’re just as concerned about a prospective supplier’s capabilities, processes, and ability to prove they can deliver what’s been promised on time and to the customer’s stringent specifications.

While cost certainly plays a major role, Department of Defense contracts are generally issued to the metal fabricator that can deliver the best value, not necessarily the best price. To determine the overall value, many RFP/RFQs for government projects require that the metal fabricator also submit two sets of documentation in addition to the cost proposal: a technical proposal and a management proposal.

We’ve shared before about what happens behind the scenes during the bidding process. While that article focused largely on determining cost, here we’ll share about the other supporting documents that outline the company’s capabilities and processes, helping to ensure that they can complete the work successfully.

What is a Technical Proposal in the Bid Process?

A technical proposal, sometimes referred to as a technical volume, is a clear written description of services, processes, and other manufacturing criteria that is required. Generally, a technical proposal contains no cost information. While each RFP/RFQ may have unique requirements for a technical proposal, in general, they include:

- An overview of technical requirements and statements of compliance

- Certifications

- Assurance of quality clauses and listing of exceptions

- High-level outline of work and responsibilities

- Project schedule for each element

- Experience and qualifications

- Quality control processes

What is a Management Proposal in the Bid Process?

A management proposal provides supporting documentation to demonstrate how well a company will manage a project. It is generally less technical in nature and provides assurances that proper processes and workflows are in place to achieve the project goals. It generally provides:

- Program management overview

- Company structure and key personnel

- Management systems

- Data management protocols

- Facility information

- Proof of past performance including testimonials

RELATED CONTENT: Metal Fabrication RFQ Guide — A Checklist of Commonly Overlooked Specifications

The Importance of Technical and Management Proposals

An experienced precision metal fabrication company that performed work for government agencies in the past likely has robust processes in place for developing and submitting technical, management, and cost proposals. The ability to articulate their technical capabilities and managerial oversight is what sets one metal fabrication company apart from others.

For starters, a company needs to prove compliance with various governmental regulations, such as DFARS clauses and securing ISO 9001:2015 and NAVSEA certifications. Lack of these requirements alone may eliminate some companies from the running.

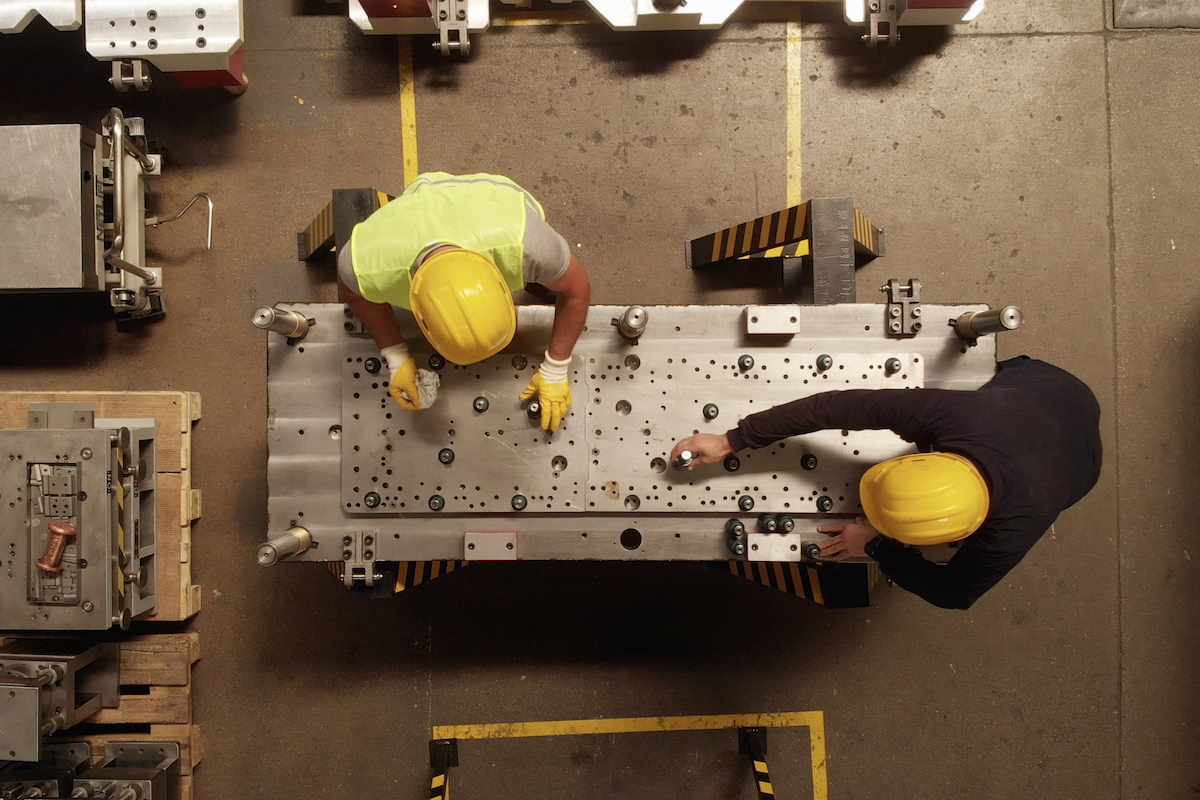

An important aspect of the proposals is the metal fabrication facility and its personnel. For example, Fox Valley Metal-Tech has an internal inspection department with procedures to follow First Article Inspections. We’ve also developed methods to organize and deliver quality data packages as part of project fulfillment. Our expanded facility features ample room and state-of-the-art equipment, plus in-house painting facilities that meet CARC military specifications that have been audited by Raytheon and Lockheed Martin to ensure compliance.

The stakes are high in the defense world. Critical applications like large electrical enclosures used for an Electromagnetic Aircraft Launch System (EMALS) on an aircraft carrier, for example, can have no margin of error. The processes and tight tolerances require extreme precision and attention to detail, which all must be proven within the proposals.

CASE STUDY: DoD Electrical Enclosures for Gerald R. Ford-Class Aircraft Carrier

In the end, a technical and management proposal demonstrates to procurement professionals how detail-oriented a metal fabrication company is. While this may seem like an ancillary factor, it can be very telling. If a submitted proposal cannot meet the RFQ proposal’s written requirements, what does that say about their ability to perform and deliver products to exacting specifications?

At Fox Valley Metal-Tech, our dedication to quality is evident based on our past work and the investments we’ve made in our people, processes, and expanded facility. That quality extends from the initial RFP/RFQ process all the way through to final delivery.

Need to issue an RFP/RFQ for complex precision metal fabrications? Contact our team today. Also be sure to reference our helpful RFQ guide below.