The Crucial Role of Project Management in Large, Complex Fabrications

To deliver a large, complex fabrication project that meets all specifications and shows up at your door on time and on budget requires more than quality craftsmanship. Yes, talented, certified teams of fabricators and inspectors are a critical aspect of success, but the way a precision metal fabrication project is managed and how it flows through a facility is equally important.

While advanced manufacturing technology helps to streamline operations, it remains a tool that is only as adept as its users. A capable and experienced project management team is the backbone of a successful build, helping to keep everyone accountable and in alignment with the project’s goals.

When vetting precision metal fabrication companies, it’s critical to also vett how their project management team will guide your project to completion. Be sure to ask the following questions.

How involved is the project management team?

A project management team should be involved in a project every step of the way, guiding it from beginning to end. They’ll participate in internal kick-off meetings along with other stakeholders to understand expectations and timeframes, and will apply lessons learned from past projects to streamline the next.

They often provide insights during the bidding process as well to ensure that obligations can be met prior to taking on more work. Right up until the project leaves the loading dock, they’ll help to keep everything and everyone on track and on budget. Despite constant changes, they provide consistency that helps to keep things flowing smoothly.

How do project managers handle scheduling?

Keeping the hundreds of details and steps organized and on schedule is among the most challenging and important aspects of project management. Large, complex fabrications may include multiple customer required hold points. Hold points are typically included in statements of work, indicating steps in the manufacturing process where production pauses and the customer inspects and confirms that requirements have been met. A project cannot proceed to the next phase of production until any potential issues are addressed and an acceptance form has been completed.

Preparing for these inspections in itself is a major undertaking, as most inspectors require a 10–15 day notice to arrange travel, and there may be as many as 15 hold points on a single project. Keeping production schedules in check so that products are ready and to the point of review is just one part. Supporting documentation, certificate records, and even eye exam records for welders and inspectors must be prepared and available for inspection and confirmation, too.

An efficient and streamlined operation will be able to work right up until the day an inspector arrives so that welders aren’t sitting idle waiting or scrambling to get done in time. Especially for defense projects, the project management team needs to be well versed in defense flow downs (program requirements), the language contained in contracts, and how to apply it to the project during every single step of the fabrication process.

How do they leverage tools and software?

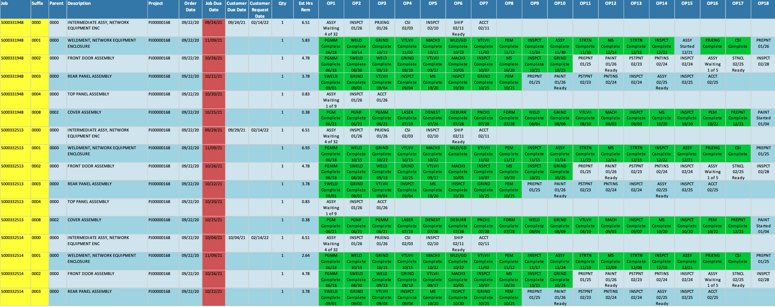

The use of enterprise resource planning (ERP) software for manufacturing helps to map out schedules and track touchpoints. The program management team also uses the ERP platform to track interactions with various stakeholders to maintain accountability. Customized reports can be shared during status update calls with customers, allowing for technical conversations and reviews based on real-time data.

The information provided includes completed operations, whether work is on schedule (green, yellow, and red status), subcontracted service updates, estimated final completion dates, and much more. Here at Fox Valley Metal-Tech, we’ve developed more than 30 customized reports (see one sample below) to extract the exact data necessary for a given situation.

Is their communication transparent and timely?

Clear and transparent communication between the production team, management, suppliers, and other involved parties is critical throughout the process, and the project management team serves as the conduit between them all. On a large-scale project, it’s not uncommon to facilitate weekly meetings with customers to provide updates on how their project is progressing. Typically, reports are sent in advance to allow enough time for review prior to the call.

It’s important to note that accountability and communication with customers needs to be a two-way street. If there are issues that require a customer’s response, such as an open supplier variation request (SVR), the project manager will outline a timeframe for the customer to respond before it impacts the schedule. A project manager will manage a project according to its original scope of work, and any engineering change orders (ECOs) from the customer will likely require adjusting the schedule and/or budget.

How do project managers address potential issues?

Due to the complexity of some fabrications, even the most perfectly planned project may experience an issue along the way. The smallest incident can create major schedule delays and cost overruns, and if someone isn’t managing the information and responding decisively and strategically, the consequences can snowball.

Some examples of potential issues might include material procurement, Design for Manufacturing (DfM) issues, overengineering, or fixtures. As a project goes through various build cycles, the project management team will constantly review how things are going and guide customers toward solutions. They may even take photos or video to help explain an issue and then coordinate next steps.

In short, the project manager serves as the glue that holds everything together. When issuing your next RFQ, take into consideration whether the prospective metal fabricator has a qualified project management team that is experienced in your industry and in managing your type of project. It’s just one more item you’ll want to check off your list. For additional RFQ considerations, be sure to download our RFQ checklist below, and contact our experts with any questions.