What You Need to Know About Jigs and Fixtures in Precision Metal Fabrication

Ultimately, a reputable precision metal fabrication company will do what it takes to deliver products to the customer’s specifications. If a customer submits a drawing of an end product, it’s up to the manufacturer to figure out how they’re going to produce it. If jigs and fixtures are required to do that, then they’ll make it happen and won’t cut corners.

Engineering teams go to painstaking measures to design complex metal fabrications, often using extremely tight geometric dimensioning and tolerancing (GD&T). What sometimes isn’t fully considered on the front end of a design, however, are the processes required to achieve the specified results.

Once a purchase order arrives at a precision metal fabrication company, there’s typically another layer of behind-the-scenes engineering that takes place to design and manufacture jigs and fixtures. These jigs and fixtures are often necessary to hold tight tolerances and ensure repeatability as part of the manufacturing process.

There may be times when the jigs and fixtures are as complex or more so than the finished product. As such, minimizing their use can lead to cost savings and better lead times for customers. A better understanding of how jigs and fixtures are used in precision fabrications can help engineers design with process in mind.

What is a Jig?

A jig is similar to a template that is temporarily mounted to a workpiece and provides a guide for the work tools being used. For example, a jig might identify exactly where a hole needs to be drilled. Jigs are often used when there are multiple identical pieces because it helps ensure precise repeatability from one piece to the next.

Example of a drill jig. The jig gets clamped to the bottom of a cabinet and is used to align a mag drill, ensuring repeatability of the drilled mounting holes.

What is a Fixture?

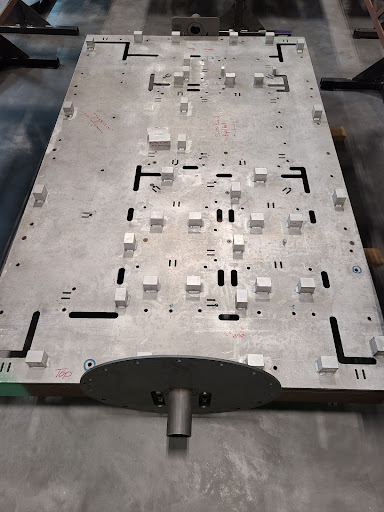

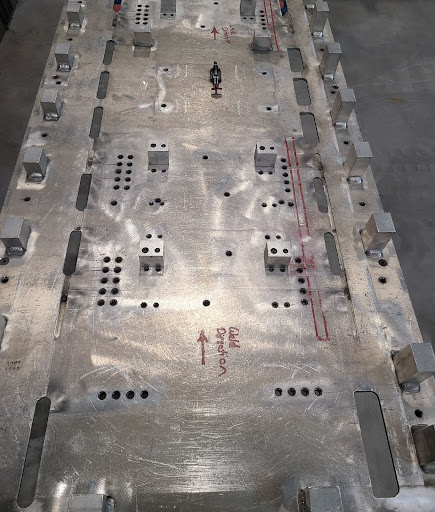

A fixture is a device that holds a workpiece securely in a fixed position to help gain efficiency and accuracy, as well as ensure repeatability. They can also help a less experienced user perform more difficult tasks. Fixtures can range from something very simple in design to highly complex designs such as the samples shown below.

Example of a rotary fixture. It positions a tube onto the centerline of a flat plate and mounts it onto a rotary table. It allows a welder to spin the part he or she is welding instead of having to move their body or the welding equipment around the part. This creates a faster, more repeatable result. It is also much more ergonomically friendly for the person welding.

Example of a machining fixture. This fixture gets clamped into a CNC machine and is used to position up to 10 small parts to be machined in a single cycle. Doing so saves time by allowing 10 pieces to be produced for every one time the doors of the machine are opened and closed. It also means the machine only needs to undergo tooling changes once instead of 10 times.

Examples of wall fixtures. Both of these fixtures are used to locate multiple parts together into a wall configuration that would then be welded together. The fixture prevents the parts from moving around while being welded and positions the parts the same way every time.

How Are Jigs and Fixtures Made?

Once it’s determined that jigs and fixtures are needed, metal fabrication design engineers will use 3D CAD software like Solidworks to develop a model and drawings. From there, the fabricator will produce the necessary jigs and fixtures, typically in-house.

Jigs and fixtures are usually made of aluminum or steel, along with a combination of clamps, locators, and/or fasteners.

How to Determine the Use of Jigs and Fixtures

In general, the more intricate a fabrication, the more likely it will require the use of jigs and fixtures. For the types of complex weldments and products produced here at Fox Valley Metal-Tech, there’s an expectation that jigs and fixtures will almost always be involved. It’s just a matter of knowing to what extent.

Years of experience have taught our project managers and engineers to recognize the need and whether it’s worth putting the time and money into creating jigs and fixtures. A lot depends on the scenario: is it a one-time build or will multiple units need to be produced? Again, repeatability is a big reason to implement the use of jigs and fixtures and a one-off project might not call for them.

However, if that single item is highly complex, a fixture will likely be needed to hold it in tolerance due to a material’s propensity for weld shrinkage, warping, or other variances during the production process.

It’s important to note that in addition to producing jigs for manufacturing processes, jigs may also be used as a quality assurance inspection tool. A jig can inform an inspector right away whether everything is in its proper location without having to take as many individual measurements. An inspection jig makes sense if there is a large run of products where it will save a significant amount of time, but it isn’t justified for a single part inspection. When used repeatedly, the jig will require periodic inspections to ensure it remains in tolerance and that no wear or damage has occured.

Minimizing the Use of Jigs and Fixtures

GD&T plays a role in how many jigs and fixtures are used due to its stringent tolerance requirements. On a commodity item, a hole drilled by hand using a tape measure and punch may be accurate enough, but likely wouldn’t comply with a .002-inch tolerance that might be included in GD&T specifications for a defense project. It begs the question of whether GD&T is appropriate in every case.

Overengineering mistakes in metal fabrication are common issues that can lead to unnecessary costs related to labor and excessive use of jigs and fixtures. Does that cable access hole in a complex electrical enclosure really need to be exactly 2.000 inches in diameter or might a slight variance that’s undetectable to the human eye be acceptable? Can slot and tab welds be used on a portion that isn’t cosmetically seen or will a more complex weldment be required? Can holes be drilled on a machine with a single fixture after welding or do they need to be drilled by hand prior to a weld which would require three or four? Such questions need to be asked during the design phase if engineers want to reduce the need for jigs and fixtures and the associated costs.

Another ancillary cost consideration is storage and handling. Jigs and fixtures need to be stored somewhere, which can mean reduced manufacturing space. Relevant documentation also needs to be tied back to each component as part of inventory control. In the event a product is reordered two years down the road, fabricators need to be able to ensure that each jig and fixture is documented and retrievable so they can be used again.

A metal fabricator’s engineering team may provide a design for manufacturability (DfM) review of specifications to determine the extent of jigs and fixtures and make recommendations that minimize their use. Some customers can be open to such reviews and are willing to administer minor adaptations to achieve greater cost savings or faster lead times. Depending on the extent of the jigs and fixtures that need to be produced, a considerable amount of time could be added to lead times, as well as cost to a final product.

The Department of Defense, however, may have already built a prototype to their exact standards and performed testing based on the documented specifications. In such cases, even seemingly minor changes to a design are typically rejected because more time and money would have to be invested in testing to prove that the variance remained structurally sound and functional. Items produced for critical national defense purposes have much stricter compliance considerations.

Ultimately, a reputable precision metal fabrication company will do what it takes to deliver products to the customer’s specifications. If a customer submits a drawing of an end product, it’s up to the manufacturer to figure out how they’re going to produce it. If jigs and fixtures are required to do that, then they’ll make it happen and won’t cut corners.

If you’re submitting an RFQ for a project, keep in mind that higher tolerances will likely need more jigs and fixtures and that it will be priced accordingly. Want to review other RFQ tips and considerations? Download our complimentary checklist below, and contact our team of experts to talk through possibilities.