Overview of CNC Machines for Precision Metal Fabrication

Computerized Numerical Control (CNC) machines are critical pieces of equipment used by precision metal fabrication manufacturers. They can help transform a solid piece of metal into an intricate shape or perfectly uniform pattern with ultra-precise tolerances.

As its name suggests, computerized programs guide various cutting tools — or sometimes guide the raw material beneath them — to form a desired shape. A major part of evaluating a precision metal fabrication company’s capabilities depends on the types of CNC machining equipment they’ve invested in. Here are several considerations.

What are Common Types of CNC Machines?

All CNC equipment uses automated, pre-programmed computer settings based on engineering specifications to produce products. CNC machining is often used as a general term in the metal fabrication industry, but there are numerous types of CNC machines, each with their own benefits and uses.

CNC Milling Machines and Routers

A CNC mill uses rotary cutting tools to drill and shave off metal from a workpiece. Depending on its type and intended function, CNC milling centers are designed to operate on either a horizontal or vertical axis, and they may also have rotary capabilities that allow for arc dimensions. Both types of machines can be designed to cut on three or more axes including X-axis, Y-axis, and Z-axis. Some have up to five or six axes.

In horizontal milling, the spindle axis is configured horizontally, meaning it will cut a piece of material that is mounted perpendicular. As you might guess, vertical milling’s spindle is aligned vertically and cuts materials that are laid flat on a horizontal surface.

Horizontal milling is generally used on bulkier materials and can produce deeper, more complex cuts. It’s also useful for pieces that require cuts on multiple sides and typically results in a smoother finish. Horizontal milling uses shorter, thicker cutting tools and is typically more costly than vertical CNC machining. Vertical milling is commonly used for drilling and single-sided projects using long, thin cutting tools.

CNC Waterjet Cutting Machines

CNC waterjets use water at extremely high-pressure to cut through raw materials. Sometimes, abrasives, like minerals, are added to the fluid to aid in the cutting process. Material selection plays a large role in which type of machining is appropriate for an application.

Those that are susceptible to expansion and contraction from the heat of other cutting methods are ideal candidates for waterjet cutting. Aluminum, in particular, is a material that is conducive to waterjet cutting due to its propensity for weld shrinkage and warping.

CNC Plasma and Laser Cutters

Plasma cutting machines are used on materials that are electrically conductive, including aluminum, steel, stainless steel and some other metals. It uses ionized gas at extremely high temperatures, basically melting the materials. It is not intended, however, for extremely high tolerances as it produces rougher edges and more slag than laser cutting.

CNC laser cutters also use heat to melt materials and can cut non-metal materials using a laser. It is able to do so with greater precision and cleaner cuts with very little thermal deformation or burrs due to its smaller point of contact. As such, it typically doesn’t require additional finishing of the cut surfaces. Laser cutting is faster than plasma cutting and will not damage surfaces, but it is also more costly.

CNC Lathes

A CNC lathe operates by spinning the material at high speed while the cutting tool is applied to the surface. It is suitable for small components, especially those with cylindrical shapes. They’re appropriate for simpler products like screws, bolts, and shafts, or for creating features like threads or drill holes.

CNC Press Brakes

CNC press brakes are used to bend or straighten metal to a shape or position it prior to welding. They use a punch and die to manipulate metal into a variety of shapes and forms to help ensure it is in the proper position prior to welding.

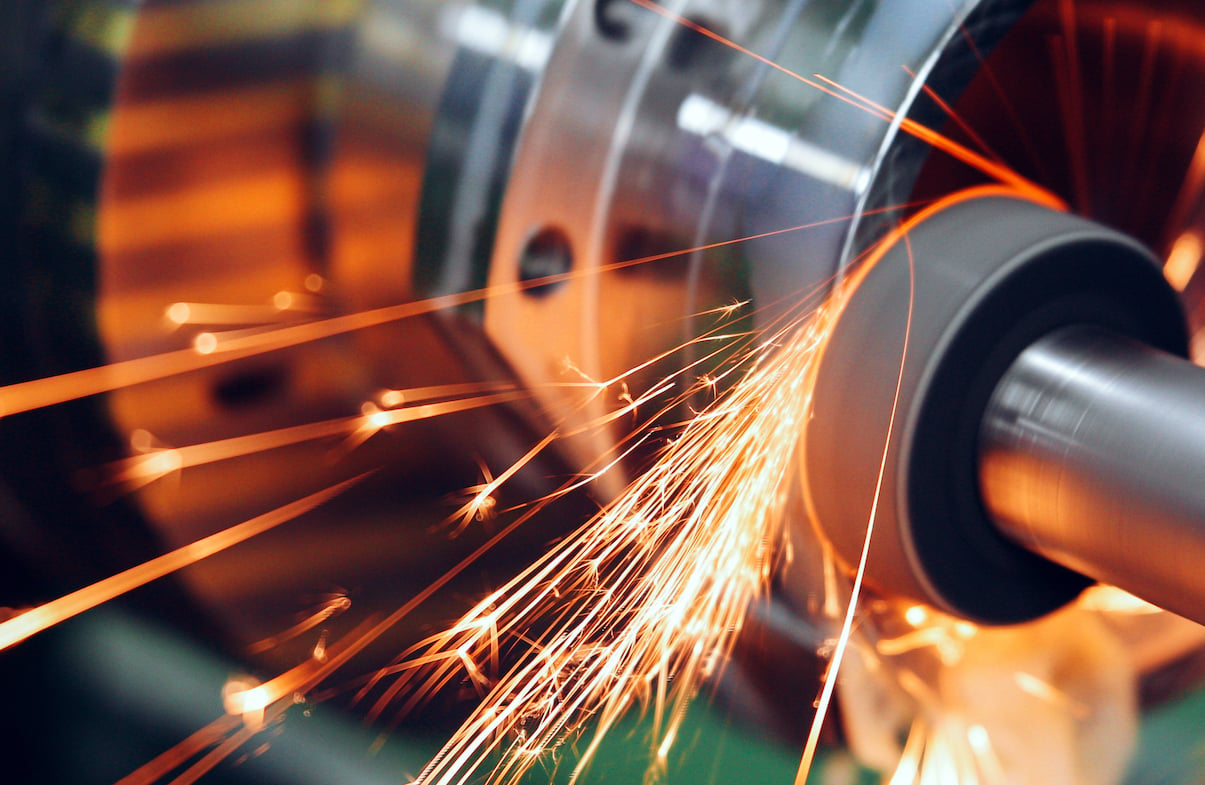

CNC Grinder

A CNC grinder is typically used as part of the metal fabrication finishing process to produce a smooth machined product. Abrasive tools, such as diamond grinding wheels, aluminum oxide, and others grind rough surfaces and can result in ultra high-tolerance finishes.

Benefits of CNC for Metal Fabrication

With the aid of CAD/CAM software, or other engineering technology, CNC machines can produce components with much more precision and speed than manual processes can achieve. It is also ideal for projects that require repeatable processes. Automation also helps to lower labor costs, enhance worker safety, decrease defects, and reduce waste.

CNC Technology Limitations

From the sounds of it, one might think that simply having the latest CNC technology might guarantee quality results. Quite the contrary. CNC machines require skilled operators to set up, load and unload, run the equipment, and inspect the results. Engineers also play a critical role in ensuring design for manufacturability (DfM) prior to a project hitting the shop floor. And, in most cases, CNC equipment is a precursor to hands-on welding, assembly, and finishing. While there are many functions that a CNC machine can perform efficiently and accurately, highly trained craftsmen and women are invaluable assets that help ensure quality results.

Modern metal fabrication companies rely on both people and state-of-the-art robotics and CNC equipment to maintain their operations and ensure quality for their customers. When inquiring about a metal fabricator’s capabilities, be sure to also evaluate their equipment and whether it is suitable for your complex project. Of course, there are numerous other factors to consider. Use our RFQ checklist below to help guide you through the process.