For Commercial and Defense Applications

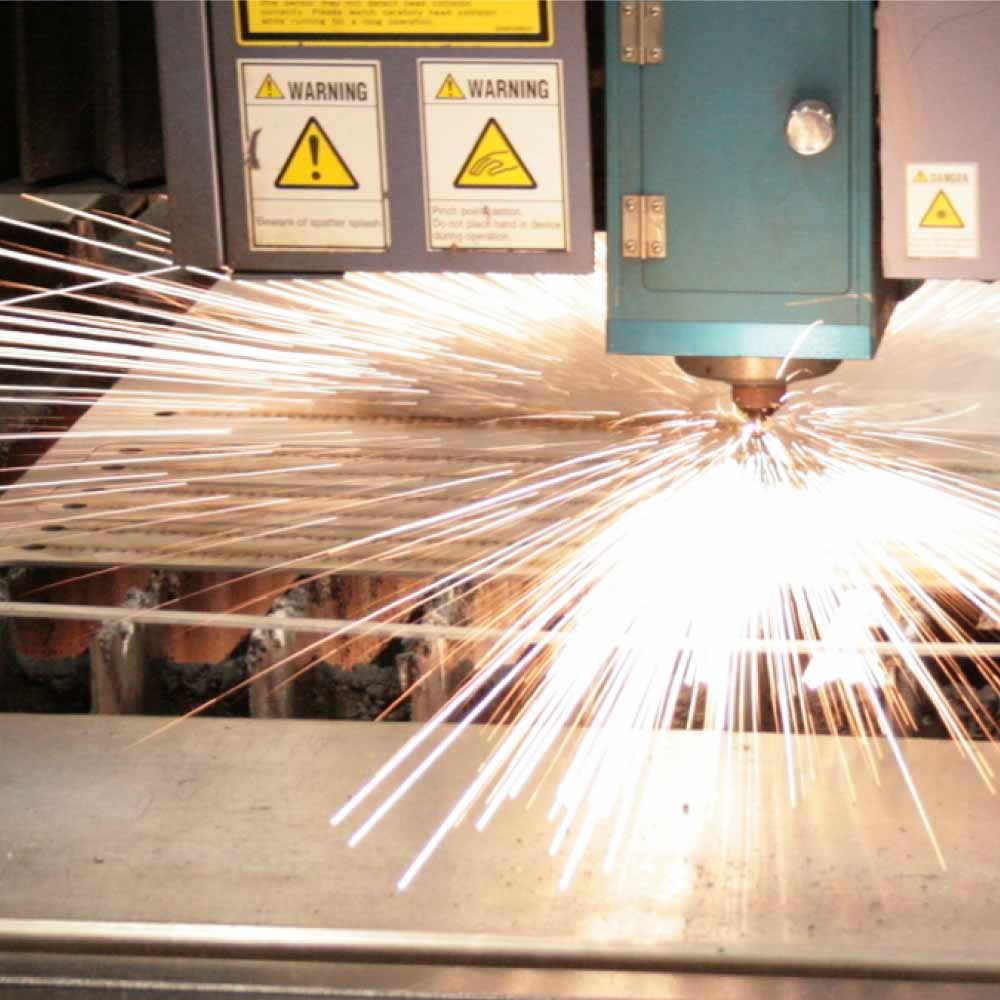

Doing things right the first time, every time, is our goal on each project, manufacturing complex fabrication per AWS or NAVSEA welding specifications. Doing the job right also includes delivering each project on time, exactly to spec.

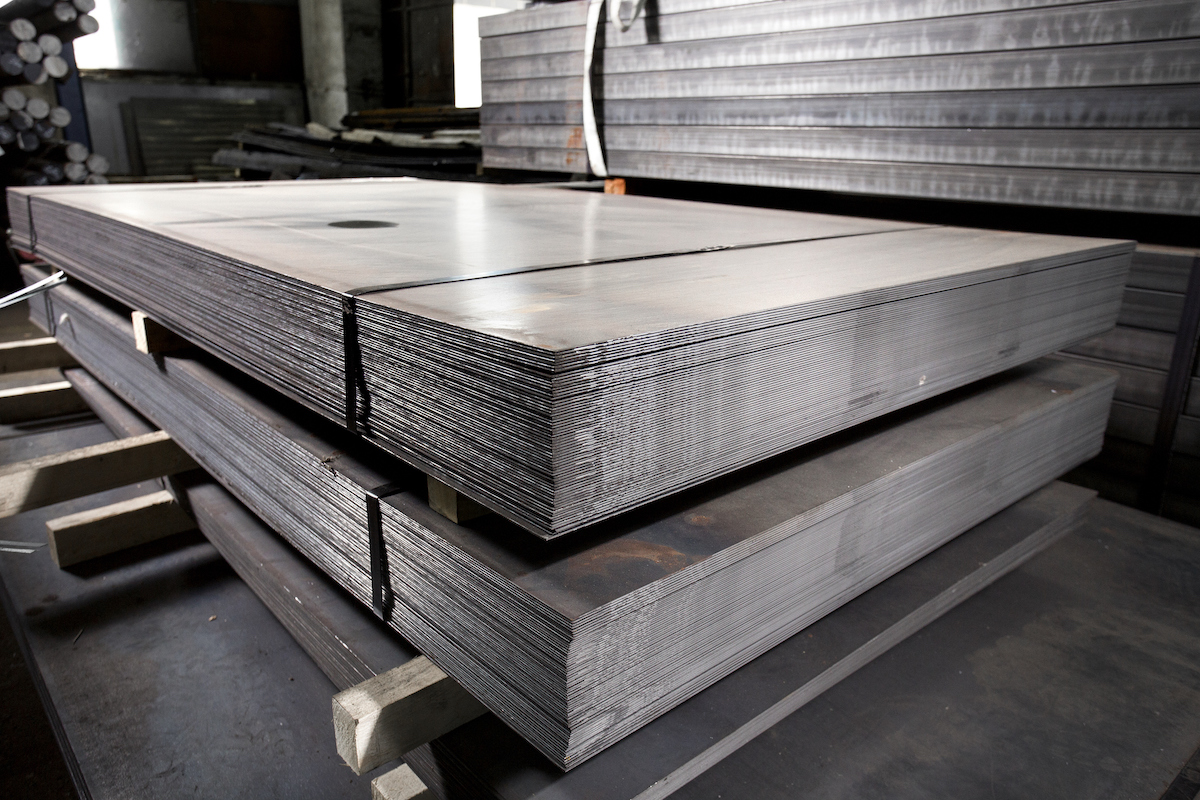

Explore our full-service capabilities to see why Fox Valley Metal Tech is a leading innovator and producer of high-quality products for commercial and defense industries.

It's What We Do

It's What We Do